"MEMS & Microelectronics Product Design & Consulting Services"

"MEMS & Microelectronics Product Design & Consulting Services"

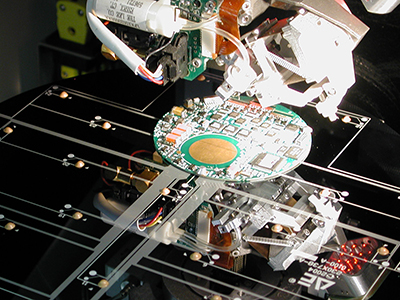

Aspen Microsystems offers product development services with a focus on microelectronic package and assembly solutions. We have over 100 years of combined experience bringing your most complex microelectronic, optical, microfluidic or MEMS device to market in automotive, medical, industrial, telecom and consumer applications. Our experience in designing complete MEMS devices and fabrication processes, circuits and systems along with our software development and test capability allow us to provide a turn-key product development service for virtually any application. Our specialization in package design and development allows the most appropriate technologies to be employed and adapts proven solutions and qualified suppliers to meet your cost, size, performance, quality and time to market requirements. The four-phase “Aspen Design Process” utilizes a combination of analytic modeling and sophisticated multi-physics CAD tools to greatly enhance the success of initial prototypes and accelerate the transition to production. Our direct experience working with wafer foundries and assembly service providers from all corners of the world, along with our “Customer First” partnership model, assures you that the most appropriate technologies will be leveraged to bring even the most challenging products to market in the most cost effective and timely manner possible.

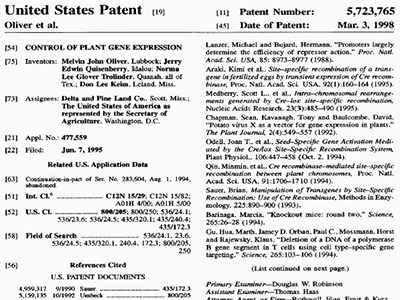

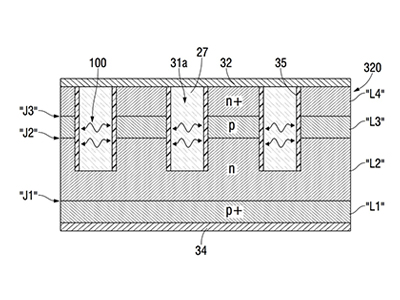

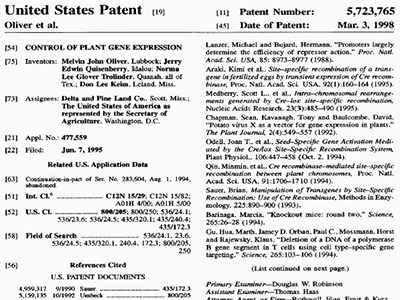

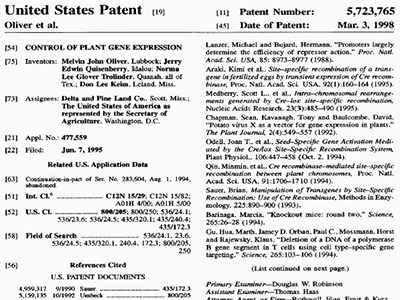

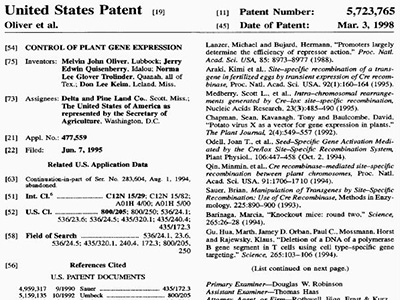

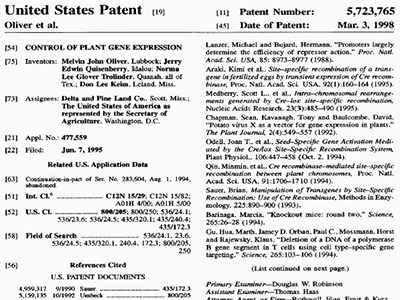

The creation, protection and defense of a company’s intellectual property is vital for success in today’s litigious marketplace. Aspen Microsystems combines deep technical knowledge in the semiconductor, MEMS, micro-optical and microfluidic industries with broad experience with IP topics to assist companies in developing and protecting their valuable intellectual property assets. We have been successful in helping customers secure patents in conjunction with the product or package development services that Aspen Microsystems offers. Companies that work with Aspen Microsystems always retain rights to IP developed during the engagement and Aspen Microsystems is committed to supporting the writing, filing and prosecution of those patent applications. Aspen Microsystems also offers patent valuation and IP assessment services to help you understand the IP landscape and to support strategic business decisions. Our experience in a broad range of markets allows accurate assessment of the value and utility of patents as well as help in identifying if patent coverage extends to a particular device or process. Aspen Microsystems also offers superior Expert Witness services with direct experience, including product teardowns and construction analysis, writing Expert Witness Reports through depositions and courtroom testimony.

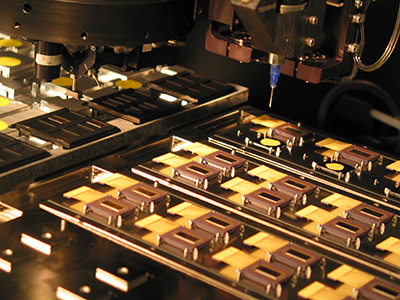

Aspen Microsystems offers consulting, engineering and instructional services in all aspects of the MEMS, micro-optical, microfluidic and microsystems industries. Decades of experience bringing sophisticated products to market, establishing high-volume manufacturing processes, as well as lower-volume custom production processes, ensures that Aspen Microsystems can help your organization utilize the latest technologies to get the most value from your production investments and to help your people deliver improved quality, higher yields and lower manufacturing costs. Whether it’s upgrading an older assembly process, assessing workflow efficiency or determining root cause for yield loss, Aspen Microsystems will enhance your company’s quality and profitability by improving your product and your process. Broad awareness of equipment suppliers and their products ensures investments are made with long-term objectives in mind. Aspen Microsystems can assist with the technical and business aspects of product planning and can plan the strategic expansion of your product into new markets. If your organization needs to expand their knowledge base in MEMS, microsystems, microfluidic or micro optical markets and technologies, Aspen Microsystems’ “case-study” based class and instructional offerings can easily be tailored to your specific needs.

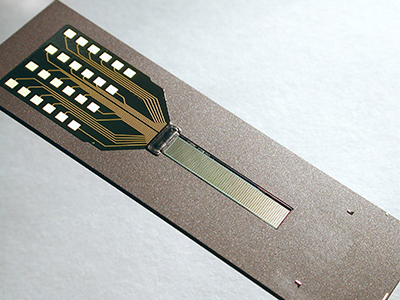

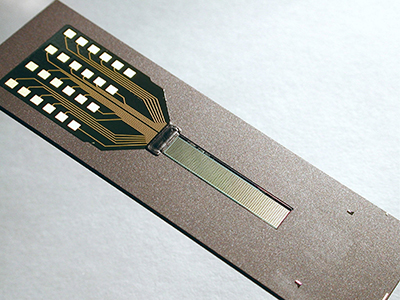

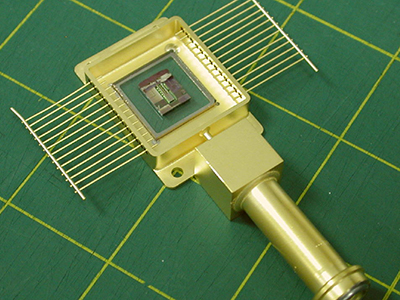

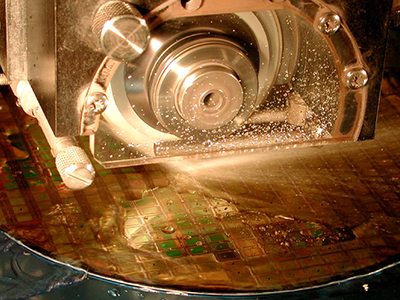

To be successful in today’s market, products must combine innovative design and well-timed technologies to create products that meet market needs. The four-step “Aspen Development Process” is a structured methodology that details the path from concept to production. This methodology was derived from decades of experience in successfully bringing a wide variety of cutting edge semiconductor-based products to market. Our practical experience in the design and development of MEMS devices, interface and calibration circuits, control systems, packages and housings, as well as complete turn-key products, provides your team with unique and critical skills that are not always readily available. We have experience with all levels of electrical, mechanical, optical, fluidic thermal and electromagnetic design and simulation and we use the most sophisticated tools, including SoftMEMS design suite, LEdit, and Solidworks, along with state of the art circuit design software to ensure the design meets specifications prior to expensive prototyping. Furthermore, our lack of exclusive relationships with service providers ensures that the most appropriate and cost-effective materials, technologies and manufacturing processes will be used throughout the design, prototype, development and manufacturing phases. Contact Aspen Microsystems to help you bring your MEMS-based product to market on-time and within budget.

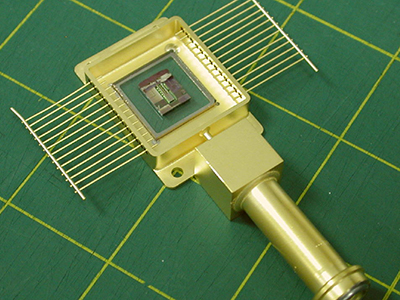

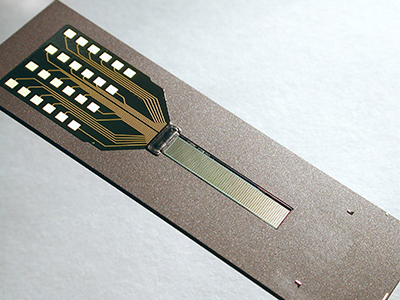

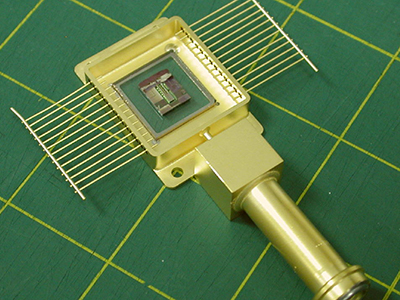

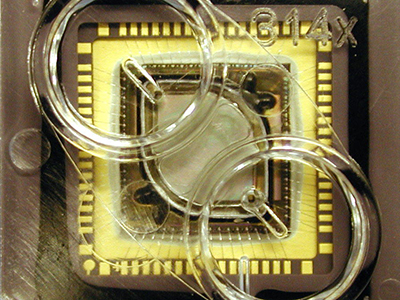

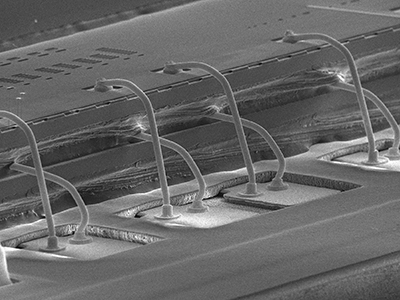

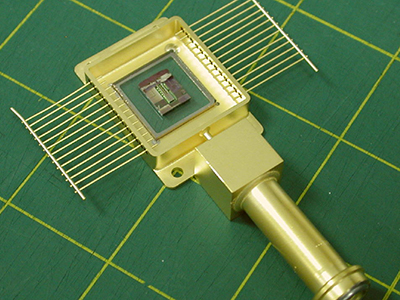

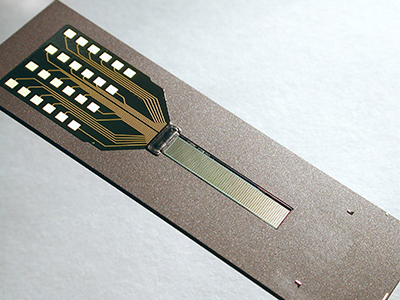

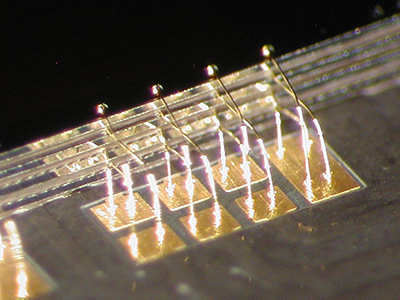

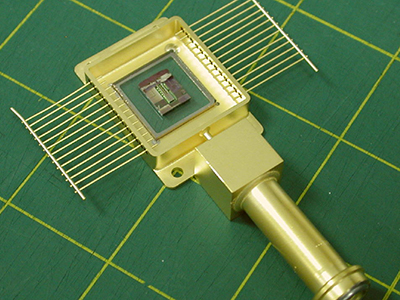

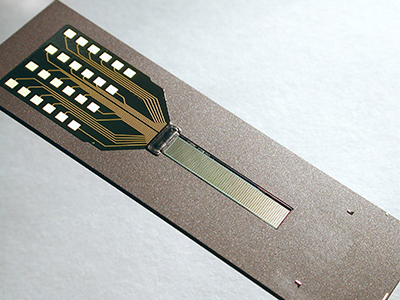

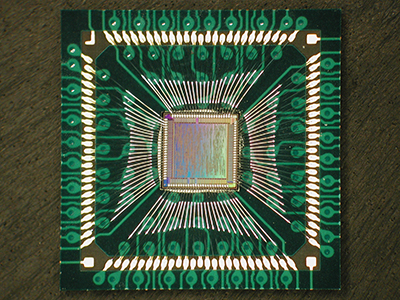

One of the most overlooked, yet most critical components in today’s MEMS and microelectronic, fluidic or optical devices is the package that houses the die and provides an interface to the system and the outside world. Since the package and assembly of a microelectronic device can be anywhere from 30% to 70% of the cost of the product, there is great opportunity to optimize a product’s cost structure through the use of appropriate package and assembly technologies. The engineers at Aspen Microsystems have developed hundreds of packages and assembly processes for dozens of different applications. We understand issues related to MEMS dicing, low-stress die attach, wirebond, flip chip, getter integration, sealing, molding and encapsulation. We have decades of experience with MEMS wafer-level packaging. We also have experience with ruggedizing your design for high temperature or high shock applications. Our CAD tools provide detailed mechanical, electrical, magnetic or fluidic analysis to ensure that interfaces to the system work as desired. Whether the product requires a high reliability hermetic package, a low cost plastic package, a wafer-scale package with TSVs, a microfluidic package, or an ultra-thin stacked die assembly, Aspen Microsystems can help your product development team bring their product to market.

The most valuable asset in any organization is its people. Products, and the technologies behind them, must evolve and stay current to keep pace in today’s rapidly changing world, and a staff with a strong, focused technical foundation is more productive and motivated in their assignments. Aspen Microsystems has developed and taught classes in topics ranging from MEMS products, device design, wafer fabrication technologies, CAD methods, MEMS packaging and assembly processes, MEMS wafer-level packaging, microfluidic packaging, as well as quality and reliability topics as related to MEMS and microsystems. These classes can be adapted to the specific needs of your organization to help grow the knowledge base of your staff and to empower them to leverage the technology in their jobs. Our “case-study” approach is derived from our extensive product development experience. In addition to valuable handouts, classes can be supplemented with an examination of physical examples to provide scale and context for the instructional topics. We can tailor our class offerings to fit half day, full day or multi-day instructional sessions so they meet the needs of your company and your staff.

The development of innovative and sophisticated products usually leads to the development of valuable intellectual property. This IP can often be one of the most critical aspects of a company’s valuation especially during their early stages of development. Aspen Microsystems has an extensive track record of developing products and packaging solutions and associated technologies that not only satisfy market needs, but that also help create a valuable IP position for their customers. Aspen Microsystems works aggressively with customers to identify patentable aspects of their products and the technology that underlies them. We support the protection of that IP by helping to prepare and submit invention disclosures and reviewing and editing patent applications, including patent specifications, drawings and claims. Aspen Microsystems also supports the response to USPTO Office Actions by offering technical advice and assessment in defense of an application. We also help you with your international patent filing efforts. We have direct experience with some of the nations top legal firms that specialize in MEMS, microsystem and semiconductor patent law and we can bring that experience to your team to maximize the value of your company.

In today’s complex technological environment and hyper-competitive marketplace, intellectual property in the form of patents can take on significant value. Owners of patent rights often find themselves competing with companies that abuse IP ownership. Conversely, innovative companies often find themselves the subject of inappropriate infringement lawsuits in an attempt to limit their business. These matters often must be settled through litigation that requires the support of an Expert Witness. Leland “Chip” Spangler, Ph.D. has successfully helped defend the intellectual property of clients in the most challenging legal environments, including sworn testimony before the US International Trade Commission. To help provide evidence to protect your IP position, Aspen Microsystems offers services include product analysis, test services, teardowns and construction analysis, on-site examinations and evidence gathering, audits, support in Markman Hearings, Expert Witness Report writing, Supplemental Report preparation, as well as legal testimony in deposition. Chip Spangler has a record of facing top lawyers in the courtroom and prevailing over their direct interrogations. Aspen Microsystems can provide support for both infringement and invalidity arguments and our extensive experience can provide the rock-solid technical foundation for legal action involving MEMS, microsystems, optical, or microfluidic devices.

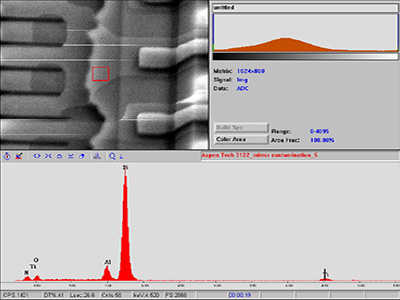

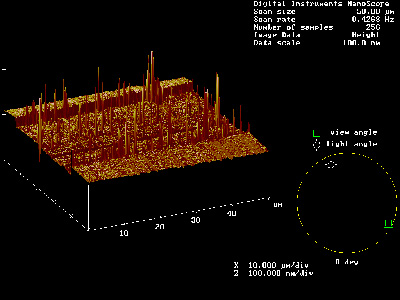

It is often difficult to uncover, decipher or document the details in sophisticated designs, materials and assembly processes that are used in today’s MEMS, micro optic, microfluidic or microelectronic products. When business motivations or legal actions motivates a deeper understanding of how a product works, how it is made, or the materials that are used, a construction analysis or product teardown effort is usually required. Aspen Microsystems can work directly with your staff to define a technical strategy to obtain this information and prepare an analysis and/or test procedure that can direct the evaluation. Aspen Microsystems can then work directly with qualified laboratories to perform the analysis and tests and deliver a report that provides the desired information. This information is often critical in making strategic business and legal decisions that can directly impact the direction of your company. Aspen Microsystems’ internal procedures ensure that your efforts remain confidential so they can be used in the most appropriate manner by your company. Aspen Microsystems also has decades of experience in reliability assessments and failure analysis. Equipment directly available to Aspen Microsystems includes SEM, EDX, X-Ray Inspection, Scanning Acoustic Microscopy, IR Microscopy, electrical testing, EDS, as well as package and die-level IC and MEMS deprocessing.

Continuous improvement across all aspects of a company’s operation is crucial in today’s hyper-competitive markets. These improvement opportunities can be found directly on the factory floor through reductions in cycle time, inventory and scrap, through workflow optimization and yield enhancements, as well as streamlining quality and documentation systems. Data collection and statistical process control methods can be developed based on the details of your operation. Aspen Microsystems’ experience from concept and product development to production ensures that every aspect of your operation can be examined to create a prioritized, continuous improvement plan based on creative and practical solutions. Yield can be improved through root cause analysis and cause and corrective actions; production efficiencies can be obtained through data-based statistical process control, work-flow and cycle time analysis, process automation and/or development of custom fixturing and material handling solutions. We have helped many companies evolve their operations to remain competitive, to increase capacity and to streamline the introduction of new products. Let our highly trained staff perform a “fresh eyes review” of your operations to help lower costs in your operations while delivering higher quality with faster cycle times.

It is often difficult to uncover, decipher or document the details in sophisticated designs, materials and assembly processes that are used in today’s MEMS, micro optic, microfluidic or microelectronic products. When business motivations or legal actions motivates a deeper understanding of how a product works, how it is made, or the materials that are used, a construction analysis or product teardown effort is usually required. Aspen Microsystems can work directly with your staff to define a technical strategy to obtain this information and prepare an analysis and/or test procedure that can direct the evaluation. Aspen Microsystems can then work directly with qualified laboratories to perform the analysis and tests and deliver a report that provides the desired information. This information is often critical in making strategic business and legal decisions that can directly impact the direction of your company. Aspen Microsystems’ internal procedures ensure that your efforts remain confidential so they can be used in the most appropriate manner by your company. Aspen Microsystems also has decades of experience in reliability assessments and failure analysis. Equipment directly available to Aspen Microsystems includes SEM, EDX, X-Ray Inspection, Scanning Acoustic Microscopy, IR Microscopy, electrical testing, EDS, as well as package and die-level IC and MEMS deprocessing.

The most valuable asset in any organization is its people. Products, and the technologies behind them, must evolve and stay current to keep pace in today’s rapidly changing world, and a staff with a strong, focused technical foundation is more productive and motivated in their assignments. Aspen Microsystems has developed and taught classes in topics ranging from MEMS products, device design, wafer fabrication technologies, CAD methods, MEMS packaging and assembly processes, MEMS wafer-level packaging, microfluidic packaging, as well as quality and reliability topics as related to MEMS and microsystems. These classes can be adapted to the specific needs of your organization to help grow the knowledge base of your staff and to empower them to leverage the technology in their jobs. Our “case-study” approach is derived from our extensive product development experience. In addition to valuable handouts, classes can be supplemented with an examination of physical examples to provide scale and context for the instructional topics. We can tailor our class offerings to fit half day, full day or multi-day instructional sessions so they meet the needs of your company and your staff.